Photograph by D Ramey Logan, Wikimedia, CC BY-SA 4.0

How Can We Make a Better Concrete Jungle

By Gayil Nalls

Sign up for our monthly newsletter!

W hen I moved to New York and experienced my first aerial view of the cityscape, I was utterly dumbfounded by the vast, human-made panorama before me. From above, the city unfolded like a vertical architectural tapestry—a dense, intricate weave of towering skyscrapers and endless stretches of concrete. It was a mesmerizing spectacle of urban ingenuity and human ambition, as iconic buildings rose dramatically over the bustling streets below. The view exemplified the term “concrete jungle,” which was more than just a metaphor—it was a physical reality. The sheer scale of this metropolis was overwhelming, a reflection of the fact that over half of the world’s population now lives in cities.

But as I studied the sight, one question lingered: How could any of this exist without concrete? It’s the foundation of modern cities, indispensable for constructing skyscrapers, roads, bridges, tunnels, sidewalks, and utility systems. Concrete’s strength, versatility, durability, and cost-effectiveness have underpinned urban growth worldwide. However, this essential material comes with significant environmental costs, including resource depletion, high energy demands, and other pressing environmental challenges.

The primary ingredients of concrete—cement, water, and aggregates like sand, gravel, and crushed stone—are resource-intensive to produce. Cement, the binding agent in concrete, is especially problematic. Its production involves quarrying large quantities of limestone and clay, which leads to deforestation, habitat destruction, and the loss of fertile topsoil. The environmental footprint of this process is substantial, disrupting ecosystems and landscapes.

The demand for sand, another key ingredient, has surged alongside urbanization. Sand mining, especially in riverbeds and coastal areas, exacerbates erosion, alters watercourses, and depletes freshwater resources. As cities continue to expand, the pressure on these natural resources intensifies, raising concerns about their long-term availability.

Cement production is also highly energy-intensive. The manufacturing process requires heating limestone and clay to temperatures of around 1450°C in a process called calcination, which consumes vast amounts of energy, predominantly from fossil fuels like coal, oil, and natural gas. This energy-intensive process is a major contributor to global energy demand.

But the energy footprint doesn’t end with production. Transporting raw materials to cement plants and delivering finished concrete to construction sites requires significant fuel consumption, further escalating its environmental cost. The overall energy demand highlights the urgent need for more sustainable practices and alternative energy sources within the industry.

Cement production alone is responsible for approximately 8% of global carbon dioxide (CO2) emissions. Beyond CO2, cement plants emit harmful pollutants like sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter, contributing to air pollution and exacerbating respiratory health issues in surrounding communities.

Water usage is another challenge. Concrete production requires large amounts of water for mixing and curing, which can strain local water resources, particularly in arid regions. If not managed correctly, wastewater from concrete plants can also contaminate nearby water bodies with harmful chemicals and sediments.

The lifecycle of concrete continues to present environmental problems even after its initial use. Demolished concrete structures generate enormous amounts of waste, much of which ends up in landfills. This raises the question: does concrete waste have to be discarded, or can it be repurposed?

To mitigate the environmental impact of concrete, several strategies are being explored. Improving energy efficiency in cement plants through advanced technologies and adopting alternative fuels can help reduce the industry’s carbon footprint. Additionally, using supplementary materials such as fly ash, slag, and silica fume can reduce the amount of clinker (the primary component of cement) required in production, thereby lowering CO2 emissions.

Concrete’s durability and thermal mass offer some environmental advantages, as these properties can reduce the need for frequent repairs and replacements. However, alternative materials must be carefully evaluated to ensure that they don’t introduce new environmental concerns.

Two promising approaches for redesigning concrete in a more sustainable future are recycling and developing green concrete. Recycling concrete from demolished structures reduces the demand for new raw materials and minimizes waste sent to landfills. By diverting concrete waste from disposal sites, recycling conserves valuable landfill space and extends the lifecycle of materials, aligning with the principles of a circular economy. This practice not only helps manage waste but also reduces the environmental burden of quarrying and transporting new aggregates. Green concrete is an evolving solution that incorporates recycled materials and produces fewer emissions during its production. These eco-friendly mixtures are designed to lessen the overall environmental impact of construction while maintaining the strength and durability of traditional concrete.

While concrete remains indispensable to modern infrastructure, addressing its environmental challenges is critical for sustainable development. By adopting innovative practices, improving material efficiency, and exploring alternatives like recycling and green concrete, the construction industry can reduce its ecological footprint and pave the way toward a more sustainable future.

The transformation of concrete production is not merely a technical necessity but a critical step toward constructing sustainable cities that can thrive without compromising the health of our planet. Innovative, eco-friendly alternatives to traditional concrete are already available, offering solutions that reduce carbon emissions, conserve natural resources, and support long-term environmental resilience. These advancements make it possible to build infrastructure that aligns with both urban growth and ecological preservation, ensuring that the cities of the future are not only durable but also harmonious with the planet’s finite ecosystems.

Gayil Nalls, Ph.D., is the creator of World Sensorium and founder of the World Sensorium/Conservancy.

References

Cement is a big problem for the environment. Here’s how to make it more sustainable

Plantings

Issue 41 – November 2024

Also in this issue:

The Healing Instinct: Plants, Animal Behavior, and the Origins of Medicine

By Gayil Nalls

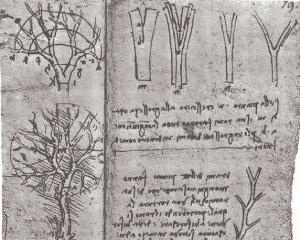

Branching Beyond Leonardo: The Evolution of Tree Architecture Theory

By Gayil Nalls

Will Plants Grow on the Moon?

By Tom Metcalfe

The Art of the Brew: Exploring Beer’s Aromas, Flavors, and Sustainability

By Gayil Nalls

Cementing Change: How Ginger Dosier’s Biomason is Paving a Greener Path

By Erum Azeez Khan

Eat More Plants Recipes:

Vegetable Tian

By Chef Romain Delacretaz, Table Marine, Nice, France

By John Steele

As Ireland transitions from the rich, smoky scent of peat-burning to a more sustainable future, its olfactory heritage is evolving. What will become the next iconic aromatic symbol of Ireland?

Click to watch the documentary trailer.