Bags made from recycled and upcycled materials. Photo by and used with permission of the 99recycle team.

Russia’s 99recycle is Bringing Recycling Home

Interview with Anton Rykachevskiy

By Braden Bjella

Sign up for our monthly newsletter!

“We’re trying to make recycled products sexy,” says Anton Rykachevskiy, co-founder and CEO of 99recycle. Starting as a few people making a recycling machine in their garage, the once-small operation has become a full-fledged recycling behemoth. Today, the brand creates chic, colorful products from recycled materials while serving as a go-to resource for businesses seeking to improve their recycling ability. Rykachevskiy discusses the history of 99recycle, how they create their work, and what’s next for the company.

Bags made from recycled and upcycled materials. Photo by and used with permission of the 99recycle team.

What inspired the creation of 99recycle?

About three years ago, we saw a project called WasteBoards from the Netherlands. It’s a project where guys catch bottle caps in the rivers around the city, then produce skateboards made out of these bottle caps. We saw some kind of magic in this process—it was very inspiring. We started Googling around, and we also found this international project called Precious Plastic, founded in the Netherlands by Dave Hakkens and some other guys. For that, they open-sourced drawings for machines you can build in your garage to recycle plastic. It’s small scale, but there’s an international community for it, and it’s growing. So we started our very small garage production using this, and we’ve made a big business out of it.

Skateboard made from recycled bottle caps. Photos by and used with permission of the 99recycle team.

But again, we started this like a hobby—just to trying to play with the recycling process to build something and to see how it works. And then, there were some turning points. The first one was when some local brands started to look at us and make orders for things made of recycled plastics. This was the first point where we saw an opportunity to make a business. The second turning point was when the father of one of the founders came to us. He has a big technology company and said, basically, ‘you’re doing some crazy stuff in the garage. Go get some grant money to develop some technological thing based on what you’re doing now.’ And so, we did that. We took a grant to build a 3D printer, and to put money into our technological development process. At the moment, this is quite a big thing in our company.

What is the process of turning discarded plastic into usable material?

First, there are several types of plastic recycling. What we do is called mechanical recycling. It’s a special process with some plastics where, if you heat them to the proper temperature, you can give them another shape. That’s the main idea of the whole mechanical recycling process.

Usually, there’s a long chain from trash to recycled- or upcycled-product. Some company collects plastic from other companies, then another company takes the collected and sorted plastic, washes it, and shreds it into small pieces. That gives you a basic raw material, and another company can take this shredded and cleaned material (of a certain type), and from there they can produce a product out of it. We implement different parts of this process into what we do. We do a little bit of collection of plastic bags, and we buy a lot of bottle caps from a local charity project that collects bottle caps in schools and in kindergartens. They sort them by color, wash them, then sell them to recyclers like us, and they use some of the money to help children with diseases.

And with those materials, we can make accessories, bags, and backpacks from recycled and upcycled materials like plastic bags. We also use extra materials from bigger manufacturers—for example, someone manufacturing boats might have small parts of material they can’t use, and we can use that as part of a bag, backpack, or something else.

Can you talk about sustainability as it relates to your work?

We have quite a big team at the moment. In the beginning, for the guys who started it, it was mostly about doing something new and something interesting. ‘Let’s try to build a machine to recycle!’ Then ‘let’s try to build a huge 3D printing machine!’ and ‘let’s try to make an accessories brand!’ and so on and so forth.

The 99recycle workshop. Photo by and used with permission of the 99recycle team.

But since then, our team and the people who have joined our team usually have very, very strong ethical reasons for joining, and very strong positions about what they think is right in terms of sustainability. We have people who are, I would say, maybe ‘obsessed’ with working very precisely with sustainability and things like even our own trash, waste, and how to manage that. We are now trying to make products from 99% recycled materials, and make it so it should be recyclable again — at least 99% of the product should be able to be recycled again. We can’t always do this, because there are some textiles that are very hard to recycle, so we repair them for free, or we’ll take them back and try to remake them again into some small accessories, things like that.

I should add that, when we talk about our mission and our main idea, we formulated it as this: we’re trying to make recycled products sexy. We’re trying to make people want to buy these things because they are cool, not just because they are recycled… But then, they know they’re made of recycled materials, and this becomes a platform to grow their interest in recycled materials.

What are your goals for the next year?

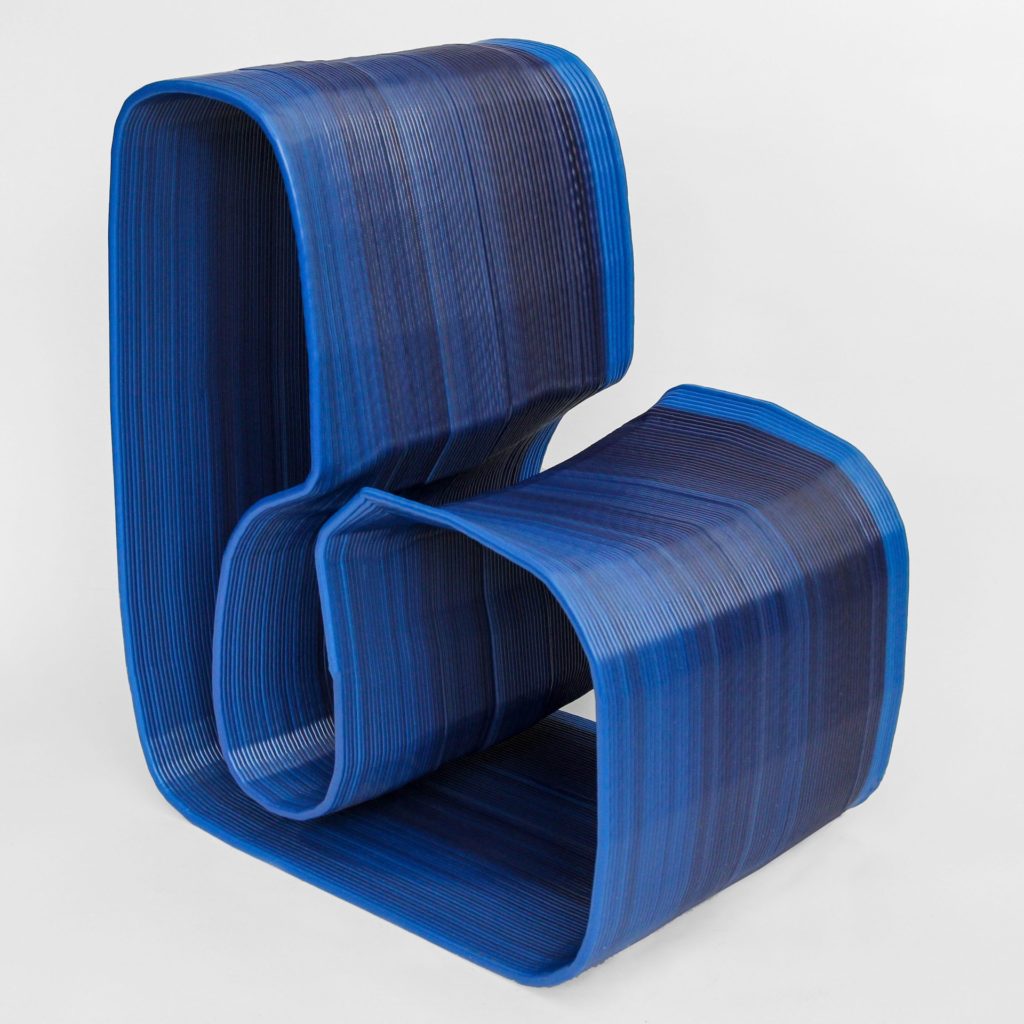

We’re now reorienting a little bit as a company. We have a very stable unit called Eburet Studio, which is our 3D printing brand and a separate brand from 99recycle, but it works with our 3D printing technology and uses recycled materials. It’s a very stable unit, and it’s growing very fast.

But for 99recycle, we’re going to save all that we have, but also reposition the company to help solve recycling problems. You come to us, you want to become sustainable, and you don’t know how. What should you do? This is where we want to come into play, because we have expertise in many different fields—textiles, plastics, other materials—and we have a wide range of experts around us in the community. We want to be the guys who know what to do at this moment, and we have the experience to do it. The next step is understanding how we present that—and how we can have the greatest impact.

Anton Rykachevskiy is co-founder and CEO of 99recycle. More from 99recycle and Eburet Studio can be found on their respective websites.

Braden Bjella is an American culture journalist based in Eastern Europe covering music, politics, history, the environment, and the intersections therein.

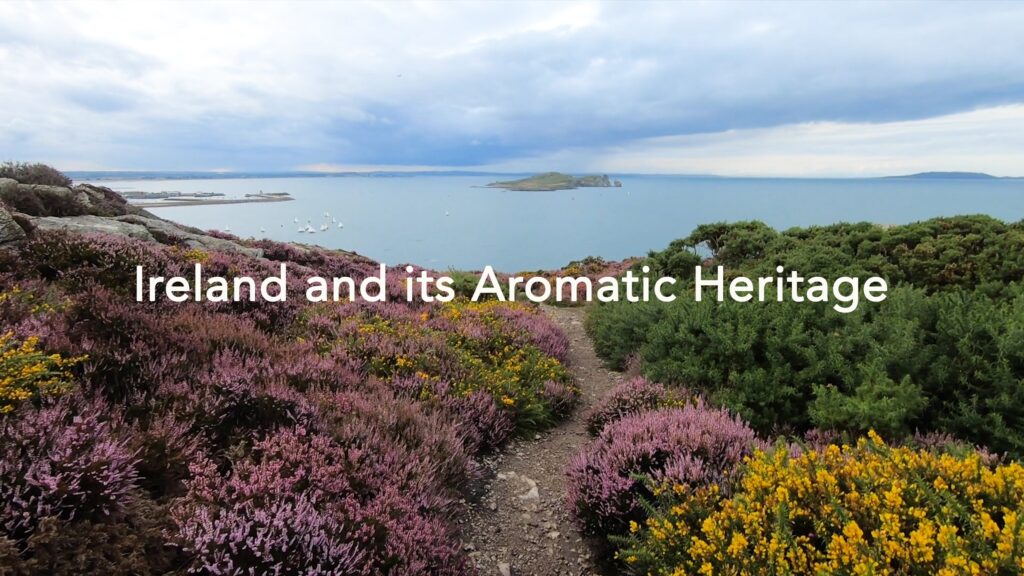

As Ireland transitions from the rich, smoky scent of peat-burning to a more sustainable future, its olfactory heritage is evolving. What will become the next iconic aromatic symbol of Ireland?

Click to watch the documentary trailer.